Trailer brake systems play a significant role in ensuring the safety of trailers and the vehicles towing them. In this post, we’re laying out the different types of trailer brake systems, their key components, and the mechanics behind how they work.

- 1) What Are the Three Types of Trailer Brake Systems?

- 2) Key Components of Trailer Brake Systems

- 3) How the Various Components of Trailer Brake Systems Work to Stop the Trailer

- 4) Final Note on Trailer Brake Systems

- 5) Free RVing Tips, Tricks, Reviews & Giveaways

What Are the Three Types of Trailer Brake Systems?

Let’s start by taking a look at the three most common types of brake systems for trailers, along with their pros and cons.

Electric Brakes

Electric brakes require a controller in the towing vehicle. This controller is responsible for managing the braking power of the trailer’s brakes. It does so when you press the brakes of the towing vehicle.

Electric brakes are the most common type of trailer brake system. They are especially useful for larger trailers and/or those carrying heavier loads.

How Electric Brakes Work

Electric brakes rely on the electrical connection between the towing vehicle and the trailer. Electric trailer brake systems consist of brake assemblies powered by electricity, installed on every wheel of the trailer, and a controller typically located in the towing vehicle. So, when the driver applies the brakes, the controller sends an electric current to the trailer brakes, activating them.

When the driver applies the brakes, the controller sends an electric current to the trailer brakes, activating them.

Advantages

Electric brake systems offer precise control and are suitable for heavy loads. They’re extremely common/popular because they’re so easy to integrate with a towing vehicle’s braking system since they’re electrically triggered.

Disadvantages

Electric trailer brakes have really only one major disadvantege: they require an electrical connection between the towing vehicle and the trailer.

Surge Brakes

Surge brakes, also known as hydraulic surge brakes, are simple mechanical braking systems most commonly found in smaller trailers. Essentially sandwiched between the towing vehicle and the trailer, surge brake systems apply the trailer’s brakes when the towing vehicle decelerates (slows down) and the trailer pushes inward (toward the towing vehicle) on the hitch.

How Surge Brakes Work

Unlike other systems, surge brakes don’t rely on an electrical connection to the towing vehicle. Instead, they operate based on the principle of hydraulic pressure. When the tow vehicle slows down, the surge in forward motion compresses a master cylinder in the surge brake actuator (mounted on the trailer in between it and the towing vehicle), forcing brake fluid to apply pressure to the trailer’s brakes.

Advantages

Surge braking systems are extremely simple and don’t require a brake controller or any electrical connections. They also have the advantage of allowing you to tow the trailer with any vehicle capable of towing the weight, without the need for any other equipment in the towing vehicle.

Surge brakes offer limited control so they’re not suitable for heavy loads.

Disadvantages

Surge brakes offer limited control of the braking pressure applied to the trailer’s brakes, so they’re less suitable for heavy loads.

They’re also not controllable from the towing vehicle, are somewhat less adjustable, and apply the trailer’s brakes whenever the trailer pushes toward the towing vehicle. This can happen on downhills when you’re not physically applying the brakes (especially if the towing vehicle has, and is using, an engine/exhaust brake to slow it down without applying the service brakes), which can lead to increased wear on the trailer’s brakes if they’re being applied at times when they may not be needed.

Hydraulic/Electric Over Hydraulic Brakes

Electric Over Hydraulic (EOH) braking systems combine the benefits of hydraulic brakes (like in virtually all cars currently on the road) and electric brakes. They use an electrically controlled hydraulic pump to pressurize brake fluid. This hydraulic pressure is transmitted to the trailer brakes, offering more control and responsiveness than surge or electric trailer brakes.

EOH systems are often used in larger trailers because they provide superior braking performance.

How Electric Over Hydraulic Brakes Work

With EOH braking systems, the trailer’s brakes are actuated by hydraulic pressure from a system that’s built into the trailer. The brakes are triggered by an electrical signal coming from the towing vehicle (this means that a brake controller, compatible with EOH brakes, is required in the towing vehicle).

Advantages

EOH brakes offer the same improvements in braking and braking control as hydraulic brakes but use the more common electric control and trigger to make them more universally compatible with the systems already available on the market.

In addition to improved control, EOH brakes are more suited for use with heavy loads.

Disadvantages

Because they incorporate components of both electric and hydraulic braking systems, EOH brakes are more complex than other braking solutions. This increases the cost of their installation and ongoing maintenance.

EOH brakes are capable of towing heavier loads.

Key Components of Trailer Brake Systems

The three most common components found in typical trailer braking systems are the brakes, controllers, and the wiring to connect the two. There are also a few other components found in surge and hydraulic brakes.

Brakes

Brake assemblies are the components responsible for creating friction and stopping the trailer’s wheels from spinning. They typically include brake shoes or pads, a drum or rotor, and other hardware. The type of brake assembly varies depending on the brake system.

Typically, brakes are built into the trailer and are designed to supply sufficient braking force to help stop the trailer so that the towing vehicle’s brakes aren’t doing all the work. This means that the combination of the tow vehicle & trailer stops more quickly (and more safely) than without trailer brakes.

Brake Controllers

Brake controllers are essential components in both electric and EOH (electric over hydraulic) brake systems. Controllers are typically installed inside the towing vehicle, allowing the driver to adjust the braking force applied to the trailer (or manually trigger the trailer’s brakes). They receive signals from the tow vehicle’s braking system and regulate the electric current sent to the trailer brakes, coordinating the stopping of the tow vehicle and trailer.

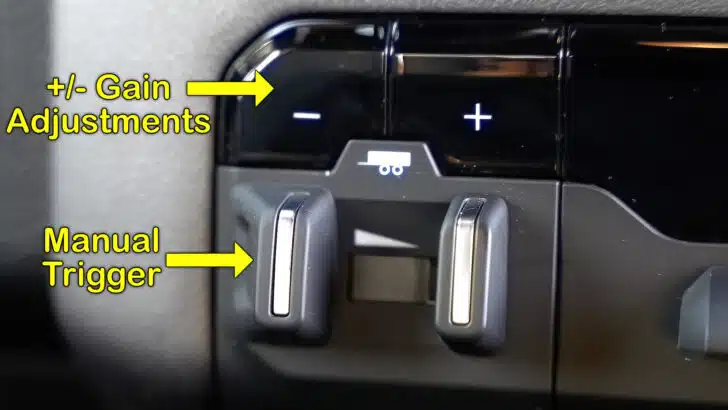

A factory-installed, integrated trailer brake controller in a modern truck offers control of the gain for the triggering signal to the trailer’s brakes, as well as a manual trigger switch.

Most popular truck brands offer factory-installed trailer brake controllers (either standard, as part of a trailering package, or as a standalone option), but there are aftermarket units available as well. They can be installed in any vehicle capable of towing a trailer (i.e. with the towing capacity, cargo/payload capacity, appropriate hitch receiver, and an electrical connection for lights, brakes, etc).

Wiring

Trailer wiring connects the brake system on the trailer and the controller in the towing vehicle. Signals are passed between the two vehicles through a 4- or 7-pin cable called the trailer wiring harness (sometimes also called “the umbilical”) that is usually permanently attached to the trailer and connects to the towing vehicle via a matching 4- or 7-pin connector mounted on/near the rear bumper.

Actuators

Actuators are crucial in surge brake systems and are typically located on the trailer tongue. Actuators are mechanical devices that respond to changes in momentum, activating the hydraulic pressure needed to engage the trailer’s brakes.

Hydraulic Lines and Fluid

Hydraulic lines and fluid are found in surge and EOH brake systems and are responsible for transmitting the pressure created by the braking action (proper maintenance of these components is essential for reliable brake performance).

How the Various Components of Trailer Brake Systems Work to Stop the Trailer

Following are summaries of how the components of each type of trailer braking system work together to slow and stop the trailer.

Electric Brake Operation

In electric brake systems, the driver activates the brakes in the tow vehicle by depressing the brake pedal. This triggers the electric brake controller, which sends an appropriate current/signal to the trailer’s brakes. The electric current energizes electromagnets within the brake assembly, pulling the brake pads against the drum/rotor and creating friction that slows down the trailer wheels.

Surge Brake Operation

With a surge brake system, when the tow vehicle slows down or comes to a stop, the forward motion of the trailer compresses a master cylinder in the surge brake actuator. This compression forces brake fluid to move through hydraulic lines to apply pressure to the trailer’s towing brakes, slowing down the trailer.

Electric Over Hydraulic (EOH) Brake Operation

Electric over hydraulic brake systems combine electrical and hydraulic components. With EOH brake systems, when the driver applies the brakes it activates the brake controller, sending a signal back through the trailer wiring harness. That signal activates a hydraulic pump, which pressurizes the brake fluid in the trailer’s brake lines. That pressure causes the brake pads to press against the drum/rotor and provides precise, proportional braking power.

Final Note on Trailer Brake Systems

A trailer brake system is a critical safety feature for both the towing vehicle and the trailer. The type of braking system you have typically depends on the trailer’s size, weight, and intended use.

Understanding the types of braking systems, their components, and how your trailer brake system operates is important to maintaining safe and efficient trailer towing.

Important: Regular maintenance and proper adjustment of brake system components are essential for reliable and safe trailer operation on the road.

For additional important information on towing a trailer, see our posts on proper trailer hitch height, breakaway cables for trailers, and learn about the best trailer brake controller options.

Free RVing Tips, Tricks, Reviews & Giveaways

As 20-year full-timers, we share everything we’ve learned about RVing over the years. Join our online community to receive a wealth of great RVing knowledge delivered daily to your inbox.

Whether you’re a new RVer or a seasoned full-timer, you’ll love the wide range of RVing topics we cover. Don’t miss a single article or any of our famous Giveaways. Subscribe to our newsletter today!

Rita

Sunday 14th of January 2024

Great article. I have electric brakes and I am wondering how do I determine what gain I need to have them at. I had read that you need to determine it by braking your towed trailer on a level straight away road but I am still not understanding it. I have a system similar to the photo in your article, factory installed in my truck. Thanks!!

TheRVgeeks

Monday 15th of January 2024

Great question, Rita. We'd suggest looking in the owner's manual for your truck. It should have step-by-step instructions for how to do it correctly. It's most likely something like the following:

Connect your trailer to the truck (cables, umbilical, etc) Park on a level, dry road Begin driving, going at about 20mph Let off the gas and, using the manual brake trigger inside the truck, apply the trailer's brakes If everything comes to a stop without the trailer's tires being dragged, increase the gain on the brake controller Repeat that process until the gain gets so high that the trailer's tires get dragged, instead of rolling while they brake Once you reach that setting, reduce the gain one notchYou also need to be sure that you have the controller set for the right type of trailer brakes... and sometimes there's even a setting for heavier trailers, which increases the output of each gain setting, since heavier trailers require more braking.